Vessel Icing

Dr. Peter Guest, Research Associate Professor of Meteorology, Naval Post Graduate School, Monterey, CA & Adapted by Robert Luke, Voluntary Observing Ship (VOS) Program LeadThe most serious form of icing affecting marine operations near the surface (ships, buoys, platforms) is from sea spray. The information provided in this article is from a Naval Post Graduate School (NPS) meteorology module that focuses on sea spray vessel icing, it will focus on what icing is, how icing can affect marine operations, the causes of vessel icing, how to predict icing situations, and how a vessel can mitigate icing.

Description of sea spray icing

|

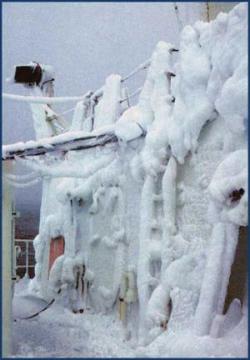

The forward bulkhead of the Research Vessel Knorr during a scientific cruise in the Labrador Sea in late winter 1997. Photographed by George Tupper. From Pickart (1997) in Oceanus Magazine. |

Sea spray icing is a serious hazard for marine operations in high latitude regions. Many ships and lives have been lost when ships sank, or became disabled, after the accretion of ice on decks and superstructures. Large amounts of ice can raise the center of mass on a ship enough to result in a catastrophic loss of stability.

Capsizing, extreme rolling and/or pitching, and topside flooding can occur as a result of the loss of stability and extra weight from the ice burden. The problem is particularly dangerous for smaller ships, such as fishing vessels, because they are more likely to be exposed to sea spray and a relatively smaller amount of ice is required for destabilization.

Ships with relatively large superstructures and low free board are more likely to experience serious destabilization problems due to icing. On any ship, communication and navigation equipment, and most any type of deck operation, can be severely impacted or rendered useless by sea spray icing.

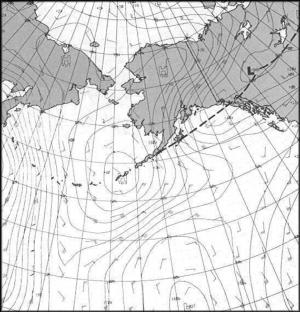

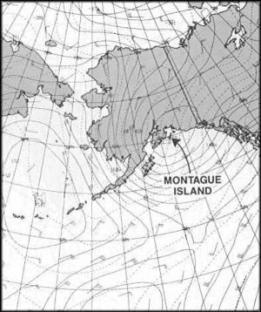

Overland (1990), Fett and Kozo (1992) and Fett et al. (1993) describe a tragic example of the effects of sea spray icing. During the period January 23-27, 1989, there was heavy icing in the Bering Sea region that was correctly forecasted to occur. Heeding the forecast, a fleet of 140 crab fishing vessels remained safe in the lee of the Pribilof Islands. By January 29, the region of heavy icing had moved to the Gulf of Alaska as forecasted. Figure 1 shows a trough that extended from a low over the Yukon toward a high over the Aleutian Islands, creating strong offshore winds over the western portion of the Gulf of Alaska. The cold air advection during this period is best seen on the 850 hPa chart from six hours earlier (Figure 2).

One crabbing vessel, the 31 m F/V Vestfjord, attempted to cross the Gulf of Alaska from the east during this period. The ship had missed the start of the crabbing season along the ice edge in the Bering Sea and the captain was attempting to make up for lost time. Whether he was aware of the severe icing forecast and chose to ignore it, or was just unable to seek shelter, will never be known. The last report came from the ship just before 1010 UTC, on January 29, approximately 60-70 nmi south of Kodiak Island when the captain reported heavy icing. By the time of the report, it was probably too late to take evasive action and the ship was never heard from again, a loss of six lives.

Causes

Sea spray icing occurs when cold, wave-generated spray comes in contact with exposed surfaces and the air temperature is below freezing. There are two general factors to be considered, environmental factors and the vessel's characteristics.

The environmental factors which affect sea spray icing are wind speed, air temperature, water temperature, the freezing temperature of water, relative wind direction, and the sea and swell wave characteristics (height, period, propagation direction.

The wind speed, air and water temperatures are the most important factors used to determine the potential for sea spray icing. With the freezing temperature of water being nearly constant, the relative wind direction can change easily and the sea height values are related to the wind.

Vessel icing can occur when the following environmental factors are present:

High Wind Speed - Usually above 18 kts or 9 m/s but sometimes lower

Low Air Temperature - Below freezing (-1.7°C or 29°F)

Low Water Temperature - Usually below 7°C or 45°F

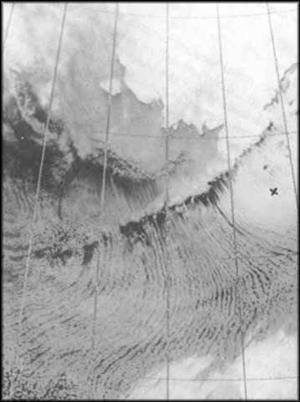

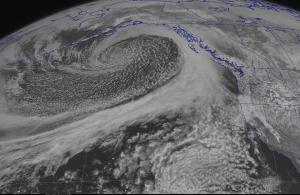

The first two factors, high wind speed and low air temperatures, are associated with cold air advection or cold air moving into a region. Cold air advection often occurs after the passage of a cold front. It is most intense when air formed over continents or ice regions (i.e. Polar Continental, Arctic and Antarctic air masses) moves over open water in the late fall, winter or early spring. Long, closely-spaced bands of low level cumuliform clouds called 'cloud streets' are a sure sign that cold air advection is taking place over water. Cloud streets are very distinctive and easy to spot on satellite images (Figure 3).

|

|

|

A dangerous coating of ice on the NOAA Ship Miller Freeman in the Bering Sea, Alaska. Such icing can affect a ship's stability and cause capsizing. Photo from the NOAA Library Ship Collection. Photo courtesy of NOAA NMAO Pacific Marine Center |

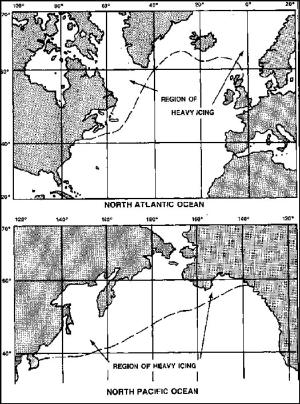

The cold advection, and associated serious icing, is most intense when an ice edge or shore is less than 200 km (108 nmi) upwind. At further distances the air becomes warmer and icing is less likely to develop. Very close (less than about 5 km or 3 mi, the exact distance is dependent on the vessel) to a shore or ice edge, waves are not developed and, hence, there is protection from icing even when the above conditions are met. In the Northern Hemisphere, icing is most likely to occur in the northern portions of the Atlantic and Pacific Oceans (Figure 4). It also can occur everywhere in the Arctic Ocean and in the Southern Ocean surrounding Antarctica.

In addition to the environmental factors discussed above, the severity of sea-spray icing depends on vessel characteristics. Icing can only occur when there is a source of water for wetting the deck, superstructure and other exposed parts of a ship. Some ship factors to consider are ship's speed, heading (with respect to wind, waves and swell), length, amount of freeboard, handling, and cold soaking aspect. In general, for the same environmental conditions there will be more sea spray reaching the ship deck, superstructure etc. when the ship is traveling faster, into the wind and waves, and for smaller ships and ships with less freeboard. Overland discusses these factors in detail. He calculated a threshold significant wave height, h1/3, and associated wind speed, for a 200 km fetch at which enough sea spray reaches the decks and superstructures to cause severe icing, assuming cold air and water temperatures are also present (Table 1).

Table 1.-Threshold Wind Speeds for Icing to Occur on Various Length Ships Parameter | ||||||

| Vessel Length meters feet |

15 49 |

30 98 |

50 164 |

75 246 |

100 328 |

150 492 |

| Significant wave height - h1/3 meters feet |

0.6 2.0 |

1.2 3.9 |

2.0 6.6 |

3.0 9.8 |

4.0 13.1 |

6.0 19.7 |

| Wind Speed at 200 km (108 nmi) fetch meters/second knots |

5.0 9.7 |

7.4 14.4 |

9.8 19.0 |

12.5 24.3 |

15.0 29.3 |

20.0 38.9 |

Note: This is only a rough guide for ships steaming into the wind and waves. The actual potential for icing depends on the type, load, and handling characteristics of a particular ship. Any captain or bridge officer who is familiar with a ship should be well aware of the wind speeds which cause sea spray to reach the deck and superstructure, and should base their assessment on the potential for icing on this knowledge.

Another ship factor to consider is cold soaking5. When a ship has been in cold temperatures for a long time (2-3 weeks for most vessels) the body of the ship will remain cold even if the air temperature is warmer. In this situation, icing may be more severe than expected given the current environmental conditions.

Prediction of Vessel Sea Spray Icing

Algorithms were developed3,4 that have proven to be useful for predicting sea spray vessel icing. These algorithms were based primarily on reports from vessels that were 20 to 75 meters in length.

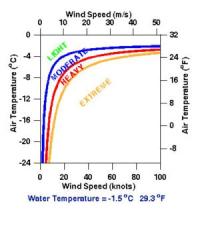

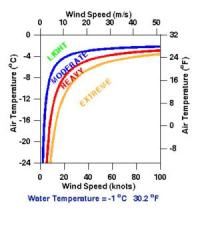

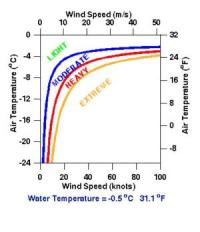

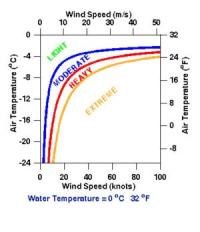

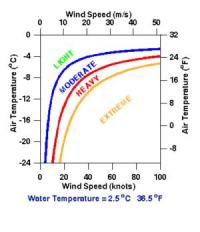

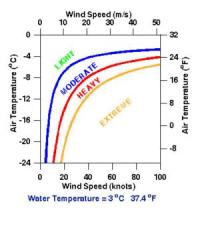

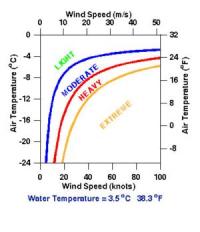

PPR = Icing Predictor

Va = Wind Speed (m s-1)

Tf = Freezing point of seawater (usually -1.7 °C or -1.8 °C)

Ta = Air Temperature (°C)

Tw = Sea Temperature (°C)

Va(Tf - Ta)

PPR = ----------------------

1 + 0.3 (Tw-Tf)

Table 2 shows the expected icing class and rates for 20 - 75 meter vessels that are steaming into the wind.

Table 2.-Icing Class and Rate

| PPR | <0 | 0-22.4 | 22.4-53.3 | 53.3-83.0 | >83.0 |

| Icing Class | None | Light | Moderate | Heavy | Extreme |

| Icing Rates (cm/hour) (inches/hour) |

0 |

<0.7 <0.3 |

0.7-2.0 0.3-0.8 |

2.0-4.0 0.8-1.6 |

>4.0 >1.6 |

These icing rates are only a guide. Actual icing rates depend on ship characteristics, cold soaking and exposure to sea spray.

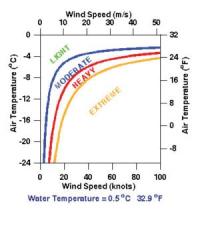

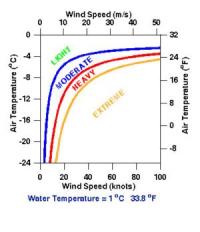

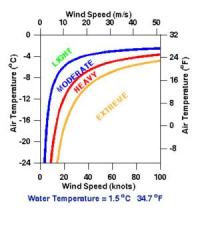

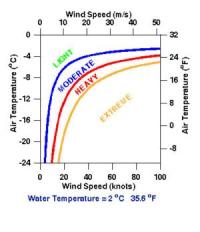

Using the Algorithm

The following nomograms have been developed for a quick reference. They display sea spray icing potential class as a function of wind speed and air temperature for a given sea temperature. These nomograms are slightly different from the ones found in US Navy5 because they are based on the most recent work by Overland3. The main difference is that the effect of cold sea water is emphasized more in the nomograms shown here. Generally, icing is not a problem at sea temperatures greater than 7°C, and no cases with higher temperatures were considered when the algorithm was derived. Because it may be possible for icing to occur at these higher sea temperatures, they have been included below.

These nomograms assume a freezing water temperature of -1.7 °C, which is typical for sea water. Icing can occur in fresh water lakes such as the Great Lakes. If you want to use the nomograms for a fresh water case, subtract 1.7 °C (-3.1 °F) from the water temperature and add 1.7 °C to the air temperature before using the tool, or just use the algorithm at the top directly and use Tf = 0. Mitigation and Avoidance of Vessel Sea Spray Icing

Weather Conditions Remember sea spray icing is associated with areas of cold air advection and cold sea temperatures. Obviously, the first and foremost way to avoid icing is to stay clear of the weather conditions that induce icing. OK, reality sets in and operational requirements make that idea a fantasy. What then? You can use the forecast guides to help you navigate the path of least icing. As a mariner, you should also be aware that Polar Lows (Figure 5) are fast-forming, intense mesoscale cyclones that are often not predicted accurately. Due to their high winds and formation in cold air, they can be associated with severe icing. Be especially aware of the possibility of a Polar Low if you are trying to avoid an icing situation. Ship Maneuvers If you are caught in a dangerous icing situation, the best thing to do is to seek immediate shelter in a harbor or downwind of a land mass such as a coastline, peninsula or island. In these regions, the wind may still be strong, but the waves will be small, thus minimizing sea spray. If shelter is not available, then steam downwind to minimize sea spray on the ship's deck and superstructures. For some ships, it may be better to minimize sea spray by heading into the seas. Do not wait until the ship has accumulated a large amount of ice. Turning through the trough can be deadly for a ship that has been destabilized by ice accretion. Preventative Coatings "Ice-phobic" (ice fearing) coatings can be applied to repel water and prevent ice build-up. Ice that does form over the coatings will be easier to remove. U.S. Navy5 recommends two ice-phobic coatings for prevention of sea spray icing on vessels:

There are problems with using ice-phobic coatings. They must be constantly reapplied because they tend to fall off when water and ice brush against them. They should not be applied to areas where people will be walking because they are very slippery. For these reasons it is not practical to use them on all susceptible surfaces. Concentrate on critical areas that are most affected by ice accretion. Ice-phobic coatings alone should not be relied upon to prevent sea spray icing, but they may help facilitate physical removal. These are hazardous materials and should used in accordance with published guidelines. Ice and Snow Removal Methods Once ice has formed it is necessary to remove it to prevent ship damage and instability. This requires advance planning. Organize crews to remove ice whenever it is safe to be on deck. Remove the ice before it reaches dangerous amounts. Usually physical removal is the most effective method.

One of the following two tools is essential; baseball bats or large wooden mallets. Stock up before you leave port and bring plenty of extras since they tend to break easily. The advantage of these heavy wooden tools is that they can remove ice effectively, but will not damage the ship and equipment as much as metal objects. The following tools are also useful: steel-bladed ice scrapers, straight bottom shovels, spades, hoes, picks, brooms, or snow shovels. The ice scraper and straight bottom shovels are useful for removing thin ice from decks. The spades, hoes, and picks can be used for thicker ice and the brooms and snow shovels remove snow that can cause problems when it gets wet and then freezes. Obviously, all these tools must be used with care to prevent damage to the ship and topside equipment. Chemicals can be used to remove ice but caution must be used when working with these items to avoid corrosive damage to your metalwork and to keep your crew safe. The most economical chemical that could be used is sodium chloride or rock salt.

1-3 can be sprinkled on decks to supplement physical removal. 4-6 can be applied with a garden sprayer to sensitive equipment that might be damaged by a bat or mallet. Follow all hazardous materials guidelines when using these chemicals. If available, the following devices are effective for ice and/or snow removal:

Although there are thought processes on the development of vessel icing and several ways of mitigating this marine phenomenon have been discussed, there is no sure way of avoiding icing conditions due to the harsh nature of the environment and the ship's routes to "get the job done." Many factors have to be considered and it is usually the seasoned experience of the captain that truly understands their ship and the situation encountered as to what needs to be done. As it has been said before, "knowledge is power." REFERENCES 1. Fett, R.W., and T.L. Kozo, 1992: Navy Tactical Applications Guide, Volume 8, Part 2, Arctic - East Siberian/Chukchi/Beaufort Seas Weather Analysis and Forecast Applications, NRL/PU/7541--92-0005, Naval Research Laboratory, Monterey, California, pp. 388. 2. Fett, R.W., R.E. Englebretson and D.C. Perryman, 1993: Forecasters handbook for the Bering Sea, Aleutian Islands and Gulf of Alaska, NRL/PU/7541--93-0006, Naval Research Laboratory, Monterey, California, pp. 302. 3. Overland, J.E., 1990: Prediction of vessel icing for near-freezing sea temperatures, Weather and Climate, pp. 5, 62-77. 4. Overland, J.E., C.H. Pease, R.W. Preisendorfer and A.L. Comiskey, 1986: Prediction of vessel icing. Journal of Climate and Applied Meteorology, pp. 25, 1793-1806. 5. U.S. Navy, 1988: Cold Weather Handbook for Surface Ships, OPNAV P-03C-01-89, Chief of Naval Operations, Washington DC. |

|||||||||||||

| Return to Table of Contents | |||||||||||||

| Return to Home Page | |||||||||||||

|

Page last modified: |